The Power of Daramic

For over 90 years, Daramic, LLC has led the way in developing new and innovative technology for the lead battery market. With headquarters in Charlotte, North Carolina, USA—Daramic is a global leader in supplying high performance polyethylene and phenolic resin-based battery separators to the lead battery industry.

Daramic operates 7 manufacturing facilities and 7 sales office globally. Each facility is strategically located, ensuring continuity of supply, short lead times and fast service.

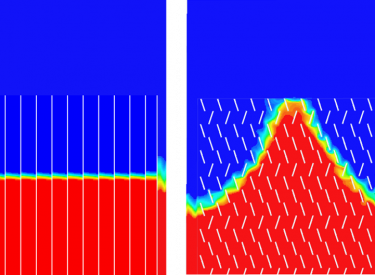

Daramic is also committed to delivering unsurpassed expertise in advanced separator technology. Three Center of Innovations in Owensboro, Kentucky, Selestat, France, and Gujarat, India serve as the central hubs for our scientists, industry experts and service technicians – all of whom have valuable industry-specific experience. Our team—combined with state-of-the-art product development, material analysis, pilot manufacturing and testing facilities—can serve as an extended resource for your technical team. Customizing products to meet specific needs, or providing assistance with field support, Daramic’s Centers of Innovation are available to you.

Daramic – Keeping the World in Motion

Company History

Production & Quality

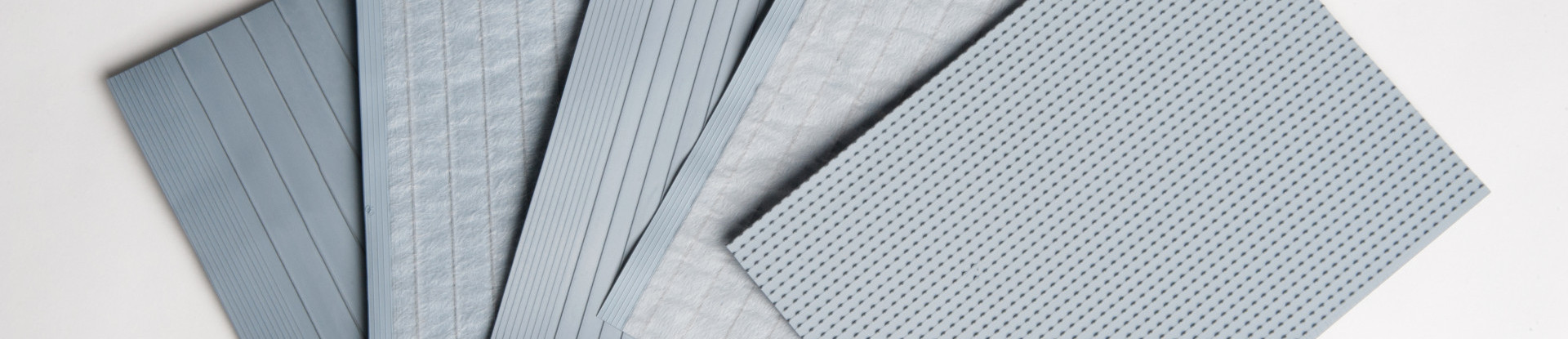

Daramic operates 7

manufacturing facilities across three continents, which meets

global production capacity, while

providing flexibility to efficiently and effectively meet the needs of customers

around the world. Consistent

implementation of the three major manufacturing process steps is key to delivering

quality across the globe.

Before products are shipped, several physical and chemical measurements are performed throughout the process. Annually, over 10,000 certificates of analysis are prepared, checked and sent to customers. More than 250 samples are produced annually to support our customer's product development, cost reduction initiatives or target new applications.